Understanding Sublimation Printing Technique

What is Sublimation Printing?

Sublimation printing utilizes sublimation ink, which can change directly from a solid to a gas without becoming a liquid. This distinctive characteristic allows for the creation of sharp, detailed, and permanent prints on a myriad of surfaces. Sublimation printing unlocks a world of creative possibilities, enabling the reproduction of complex designs and photographs with exceptional accuracy and clarity. To truly understand sublimation printing, it's important to explore its main ideas, how it works, and its advantages over traditional printing.

The magic of sublimation printing lies in the heat press. When subjected to the optimal combination of heat and pressure, sublimation ink transforms into a gas and infuses itself into the pores of the substrate, effectively becoming one with the material. This unique bonding process results in prints that are not only visually stunning but also remarkably resistant to fading, washing, and general wear and tear.

Compared to traditional printing methods like screen printing or direct-to-garment (DTG) printing, sublimation offers a host of advantages.

Firstly, sublimation delivers unparalleled color vibrancy and saturation. As the ink permeates the substrate at a molecular level, the resulting prints exhibit exceptional brilliance, depth, and richness.

Secondly, sublimation printing enables the reproduction of intricate details and gradients with remarkable precision. The process allows for a high level of accuracy, capturing the subtleties of photographs and complex designs that would be challenging to achieve with other printing techniques.

Thirdly, sublimation prints boast impressive durability. The ink becomes an integral part of the material, making the prints resistant to fading, cracking, and peeling. Even after numerous washes or exposure to harsh environmental conditions, sublimated prints retain their vibrant colors and overall quality.

Lastly, sublimation offers extensive customization options. From personalized apparel with individual names and images to bespoke promotional products, sublimation allows businesses and individuals to create unique and memorable items tailored to their specific needs.

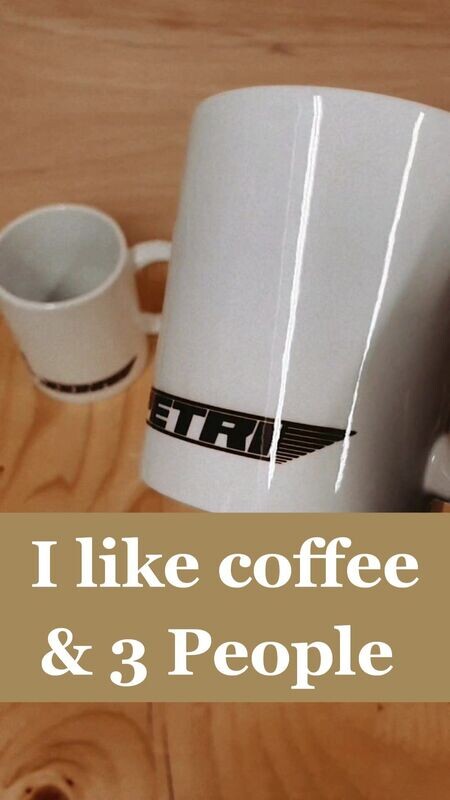

Sublimation printing is compatible with an extensive array of materials, ensuring its versatility across diverse industries. Some of the commonly used substrates include polyester fabrics, ceramic mugs, aluminum sheets, polymer-coated surfaces, and even certain types of wood. The flexibility in material choices expands the horizons of creativity, empowering businesses and individuals to explore new avenues of expression.

Benefits and Advantages of Sublimation

The allure of sublimation lies in its numerous benefits and advantages, making it a sought-after printing method across various industries.

- Vibrant and Long-Lasting Colors. Sublimation prints exude an unmatched vibrancy thanks to the ink's ability to bond deeply with the substrate. The resulting colors are vivid, sharp, and resistant to fading, ensuring that the prints remain visually appealing and impactful over an extended period.

- High-Quality and Detailed Prints. Sublimation printing enables the reproduction of intricate details, gradients, and complex designs with exceptional precision. The process captures the subtle nuances, ensuring that the final prints exhibit outstanding clarity and depth.

- Durability and Resistance to Fading. Sublimation prints are highly durable and resistant to fading, cracking, and peeling. The ink becomes an integral part of the material, making the prints impervious to washing, exposure to sunlight, and general wear and tear.

- Customization Options for Personalization. One of the greatest strengths of sublimation printing is its ability to personalize products. Whether it's adding individual names, photographs, or custom designs, sublimation allows for limitless customization options. This versatility empowers businesses to create unique, one-of-a-kind products that resonate with their customers.

- Versatility in Terms of Printable Materials. Sublimation printing can be applied to an extensive range of materials, including fabrics, ceramics, metals, and more. This versatility enables businesses and individuals to explore new creative possibilities, reaching diverse markets and catering to a broad range of needs.

- Cost-Effectiveness for Small and Large-Scale Production. With advancements in technology and increased accessibility, sublimation printing has become a cost-effective solution for both small and large-scale production. The ability to create high-quality prints without the need for extensive setup or color separation makes sublimation a practical and efficient choice for businesses of all sizes.

Tips for Successful Sublimation Printing

To ensure optimal results in sublimation printing, attention to detail and adherence to best practices are essential. Here are some valuable tips to achieve success in your sublimation printing endeavors:

- Proper Color Management and Calibration. Calibrating your sublimation printer and monitoring, and maintaining accurate color profiles, are crucial for achieving consistent and accurate color reproduction. Regular calibration ensures that the colors in your design appear as intended on the final print.

- Choosing the Right Substrate for Printing. Not all materials are suitable for sublimation printing. It is important to select substrates that have been specifically coated or designed for sublimation. The quality and compatibility of the substrate can greatly impact the final print results.

- Ensuring Clean and Properly Prepared Surfaces. Before printing, it is vital to ensure that the substrate surfaces are clean and free from dust, lint, or any contaminants that may hinder the adhesion of the ink. Proper surface preparation guarantees optimal ink transfer and ensures the longevity of the print.

- Avoiding Common Sublimation Printing Mistakes. Common mistakes in sublimation printing include using incorrect heat and pressure settings, not securing the substrate properly, or not aligning the design accurately. Familiarize yourself with potential pitfalls and adopt best practices to avoid costly errors and wasted materials.

- Troubleshooting Tips for Achieving Optimal Results. In the event of unexpected results or issues during the sublimation process, troubleshooting skills can prove invaluable. Understanding common problems such as color bleeding, ghosting, or inconsistent transfers will help you identify and resolve issues efficiently, leading to improved print quality.

IN CONCLUSION, the versatility and benefits of sublimation printing have revolutionized the world of printing and product customization. Whether in the apparel industry, promotional products, or a myriad of other applications, sublimation opens up a universe of vibrant and personalized possibilities. As you explore the creative potential of sublimation, let your imagination soar and embrace the exceptional power of this transformative printing technique.

The wide-ranging uses of sublimation printing continue to evolve, driven by technological advancements and the creative ingenuity of businesses and individuals. Embrace the world of sublimation, unlock its potential, and elevate your printing endeavors to new heights. Let the vibrant colors, durability, and customization options of sublimation printing be your gateway to captivating and unique creations.